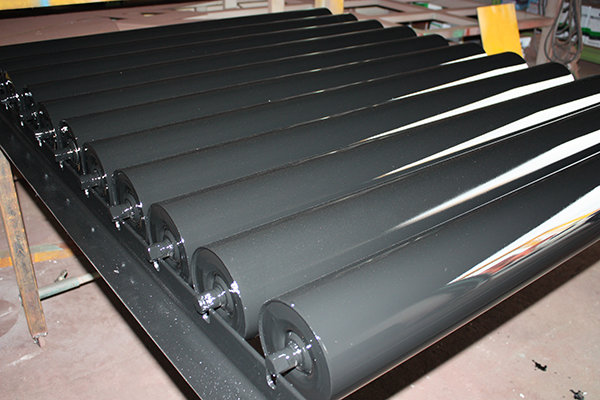

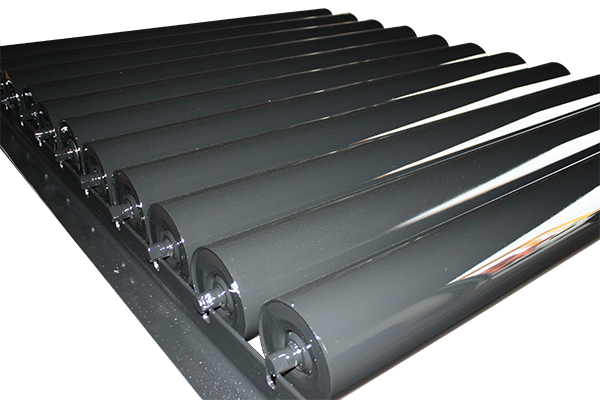

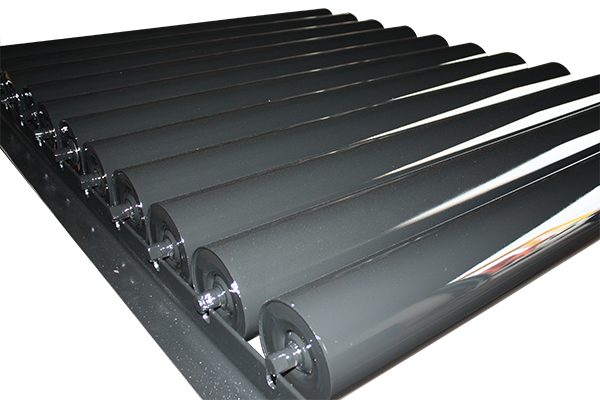

We make a wide range of Roller Conveyors classified as – Powered and non powered version conveyors using standard Precision bearings for heavy loads (250 kgs and above) and pressed bearings for lighter loads.

Many combinations offered in terms of Roller Pitch, Roller Diameter, Roller Moc, between frame width. Rollers are spring loaded with Hex axle or round axle. Please ask for our detailed catalogue

CONVEYOR ROLLERS

We are topmost provider of Conveyor Roller to our clients available in various dimensions and options.

Features:

- Precise dimensions

- Quality approved

- Excellent finishing

Specifications:

- Length: As per specified

- Voltage Requirement: Optimum or as per given

- Minimum quantity: 1

Use:

- Conveying Applications

Gravity Roller Conveyors are ideal for applications that require an economical, non-powered means for conveying material. They are excellent for both permanent and temporary conveyor lines; used in production lines, warehouses, shipping departments and assembly areas. Gravity Roller Curves and spurs add to the versatility of straight conveyors. There are several styles of Gravity Conveyors including: roller conveyors, skatewheel systems and ball transfer tables and carts.

The below chart lists “standard” Gravity Conveyors in which we manufacture with highly competitive pricing and lead times.

GRAVITY CONVEYORS

In order to fulfill the changing demands of our clients, we are offering a quality range of Gravity Conveyors. These roller conveyors are widely used to carry lightweight packages. The offered machines are useful in setting up permanent or temporary conveyor lines in shipping departments, warehousing activities and assembly areas. Before the final dispatch, these conveyors are thoroughly checked by the quality analyzers on varied parameters to ensure their flawlessness.

Gravity Feed Roller Conveyor

Owing to the assiduous efforts of our team, we have been capable of import the best quality Gravity Feed Roller Conveyor. Manufactured using high-grade metals and alloys, the offered product is highly durable in its characteristics. Resistant to corrosion, abrasion and wear & tear, the entire range of conveyors offered by us is highly popular.

Features:

- High working efficiency

- Long lasting

- Robust construction

- Superb finish

Specifications:

| Model | Gravity Roller Conveyor |

| Roller Type | Zink Steel Roller |

| Width (Mm) | 600 |

| Diameter of Roller (Mm) | 50 |

| Min Height (Mm)/td> | 125 |

| Length (mm) | 1000(Expandable) |

| Speed Mt/Min | Nil |

| Power | Nil |

| Source | Nil |

Gravity Conveyor Rollers Manufacturer in India

We manufacture a wide range of Conveyor Rollers that includes light duty PVC gravity rollers to the heavy duty pallet handling rollers. The materials which we used in manufacture the Conveyor Rollers are of various types which consists , Mild Steel, Galvanized or Zinc Plated and Stainless Steel.

We provide gravity rollers of various shaft sizes with the diameters of 12mm to 14mm. We have capacity to produce single Gravity Roller to thousands of conveyor rollers at a given time for all type Gravity Conveyor or Conveyor Chute.

We manufacturing conveyor rollers since 2001 and from the inception year we have been achieving the success in designing and executing the conveyor systems projects. Our Conveyor Rollers are made of the best quality of raw materials which is sourced by global market.

Not only that, We have expertise in Manufacturing all types of Gravity Conveyor that includes Flexible Conveyor, Straight Conveyor, Curve Roller Conveyor to fulfill your appropriate requirement. We have the option of ‘make to order service’ through which we can manufacture Gravity Conveyor with customized option of clients. For more information you can easily browse through the range of Gravity Conveyer and you can call us any time for any type of Gravity Conveyor requirement or any Conveyor products and service

Features & Specialities:

- Free running bearings.

- Mild steel, stainless steel

- Wide range of tube and spindle options.

- Capacity to handle from 1gramme up to 200kg per gravity conveyor roller.

- Our most competitive priced roller

Applications:

- Indoor Transportation

- Package Goods

- Warehousing

- Cartons

- Light Weight Product

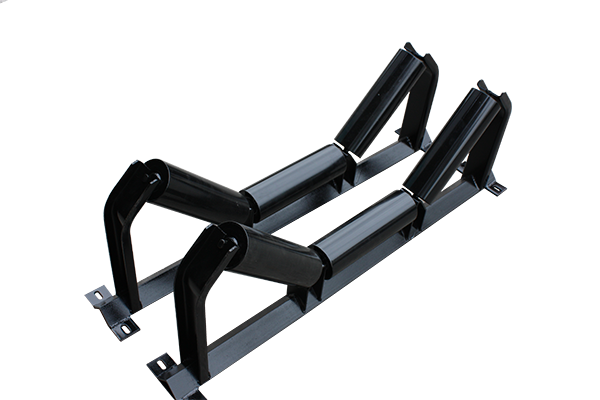

Conveyor Idler

Our organization deals in offering Conveyor Idler to our clients at reasonable rates.

Features:

- Light weight

- Robust

- Accurate dimensions

Specifications:

- Category: Idler

- Dimension: Standard and customized

- MOQ: 1

Application:

-

- System component for conveyor structure used for moving bulk materials

- Modify your troughing angle to maximum material transport based on belt speed and material characteristics

CONVEYOR IDLER ROLLERS

We are the well established manufacturers and exporters of Conveyor Idler from India. A belt conveyor roller consists of two or more pulleys, which are powered and move the belt and the material forward, and an unpowered pulley that is called the idler. Our range of Conveyor Idler is available in different sizes and ratios to suit varied requirements.

This Conveyor Idler is suitable for harsh operating conditions and is demanded in the market for their corrosion resistance, easy operations and flexibility. We offer precision engineered Conveyor Idler that are fabricated using fine raw materials and these are widely appreciated across the nation for its durability, accurate dimensions and sturdy construction.

Our extensive range of Conveyer Idler is widely used in mining, processing and handling processes. The Conveyer Idler & Pulley both bearing cups are welded in Double Headed automatic welding Machine. Bearing sealing area is machined. Our Conveyor Idlers are manufactured to ISI standards.

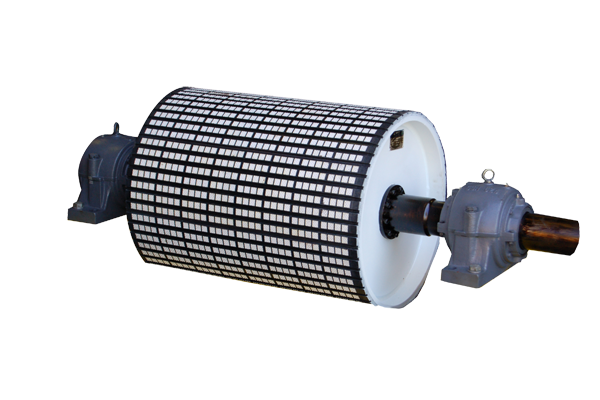

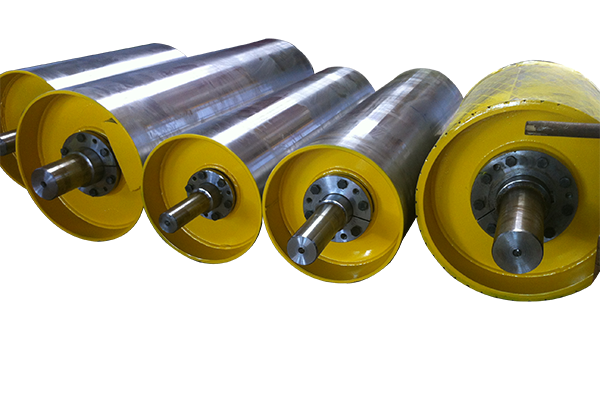

BELT CONVEYOR PULLEY

With a focus on the ever-evolving requirements of our customers, we have come up with a wide assortment of Belt Conveyor Pulley. Our adept workforce use supreme quality raw material with the aid of progressive methodology in the manufacturing process of this pulley. For ensuring its quality and durability, the provided pulley is rigorously tested on different measures of quality in compliance with set international industry standards. Apart from this, our clients can avail this pulley in different specifications at a rock bottom price.

Feature:

- Easy to install

- Long service life

- Accurate dimension

Conveyor Pulley

Tailor-made for the Most Varied of Conveying Applications

Bulk handling systems are moving to larger conveyors and increased capacities. The high modules, high tension belts require pulleys of much higher capacity and durability than standard units. Engineered Class Pulleys are supplied with various hub and bushing systems including keyless locking devices used on profiled and cast disc designed pulleys, which are prevalent on high tension steel cable belt systems

CONVEYOR PULLEYS MANUFACTURERS

We are a leading manufacturer and exporter of Conveyor Pulley. Fabricated from finest quality raw material, these Chain Couplings find diverse application in various industries.

INDUSTRIAL CONVEYOR ROLLERS

We are one of the prominent manufacturers and supplier of the Industrial Conveyor Roller. These are the special kind of gears that are manufactured in accordance to the industry regulated norms. We fabricate these by using high quality raw material and are also used to cushion the vibration noise in various application areas in fastening industry. The pulling tension is decreased by putting the rollers close together. Our range of Industrial Rollers is widely used in various industries like steel, paper, textile, printing, plastic, lamination and cement industries. Further, we also provide customization as per the specific requirements of our valuable clients.

INDUSTRIAL ROLLERS CONVEYOR

We are one of the prominent manufacturers and supplier of the Industrial Roller Conveyor. These are the special kind of gears that are manufactured in accordance to the industry regulated norms. We fabricate these by using high quality raw material and are also used to cushion the vibration noise in various application areas in fastening industry. The pulling tension is decreased by putting the rollers close together. Our range of Industrial Rollers is widely used in various industries like steel, paper, textile, printing, plastic, lamination and cement industries. Further, we also provide customization as per the specific requirements of our valuable clients.

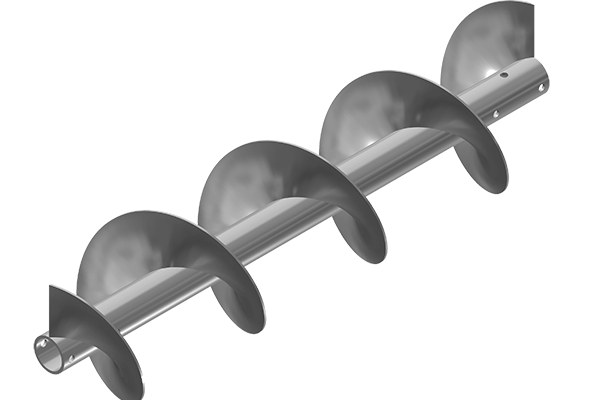

Screw Conveyors

We are the leading manufacturer of high quality Screw Conveyors (U Trough Conveyors). We fabricate Screw Conveyors using high quality raw material. Our range of screw conveyor is used in many industries for various kinds of applications like handling Fertilizer, Sand, Seeds, Grain and Ash etc. We offer screw conveyors of the capacity ranging from 5 ton per hour to 60 ton per hour. Our range of Screw conveyors are highly demanded in industries like chemical factory, sugar factory, cattle feed factory and many more. We provide these Screw conveyors as per the need of clients which are highly efficient in use

conveyor rollers suppliers

Product Description :

We make a wide range of Conveyors Ropper classified as – Powered and non powered version conveyors using standard Precision bearings for heavy loads (250 kgs and above) and pressed bearings for lighter loads.

Many combinations offered in terms of Roller Pitch, Roller Diameter, Roller Moc, between frame width. Rollers are spring loaded with Hex axle or round axle. Please ask for our detailed catalogue

Conveyor

We follow international standards of quality while manufacturing our range of Roller Conveyors. These conveyors are classified as powered & un-powered roller conveyors and are used for applications ranging from medium to heavy loads. We pay attention even to the minutest detail as we engineer each roller from ERW pipe and provide bearings and stationary shafts at both the ends. These rollers are assembled in a frame in such as manner that one or the other roller can be removed anytime without even disturbing adjacent rollers.

Specifications:

- Modular construction

- Available in standard length of 2500 mm

- Adjustable leg supports for easy installation and leveling at site.

Our range of un-powered rollers does not require any power to get operated and the conveying of components is done by pushing the component or by gravity. We also design and develop angle of declination for gravity roller conveyors after considering the load of the component.

These rollers are free to move and possess following specifications:

- MOC – MS, SS 304, SS 316

- MOC for Frames – MS powder coated, SS 304, SS 316

- Rollers – galvanized, chrome plated or PU coated

Optional attachments:

- Adjustable / fixed side guides

- Castor wheels for easy movement of conveyors.

- Drip trays

- Impact zones for impact loading

- Pneumatic lifters, stoppers, pushers etc

CONVEYORS

Roller Conveyors

We follow international standards of quality while manufacturing our range of Roller Conveyors. These conveyors are classified as powered & un-powered roller conveyors and are used for applications ranging from medium to heavy loads. We pay attention even to the minutest detail as we engineer each roller from ERW pipe and provide bearings and stationary shafts at both the ends. These rollers are assembled in a frame in such as manner that one or the other roller can be removed anytime without even disturbing adjacent rollers.

Specifications:

- Modular construction

- Available in standard length of 2500 mm

- Adjustable leg supports for easy installation and leveling at site.

Our range of un-powered rollers does not require any power to get operated and the conveying of components is done by pushing the component or by gravity. We also design and develop angle of declination for gravity roller conveyors after considering the load of the component.

These rollers are free to move and possess following specifications:

- MOC – MS, SS 304, SS 316

- MOC for Frames – MS powder coated, SS 304, SS 316

- Rollers – galvanized, chrome plated or PU coated

Optional attachments:

- Adjustable / fixed side guides

- Castor wheels for easy movement of conveyors.

- Drip trays

- Impact zones for impact loading

- Pneumatic lifters, stoppers, pushers etc

ROLLING CONVEYOR

We strive to deliver the quality products such as Conveyors, Roller Conveyors, Belt Conveyors, Screw Conveyors, Slat Conveyors, Chain Conveyors, Apron Conveyors, Bucket Elevators, Material Handling Equipments, Rotary Feeders, Inclined Conveyors, Transfer Turn Tables, Loading Conveyors, Pinch Roll Assembles, Storage Silos.

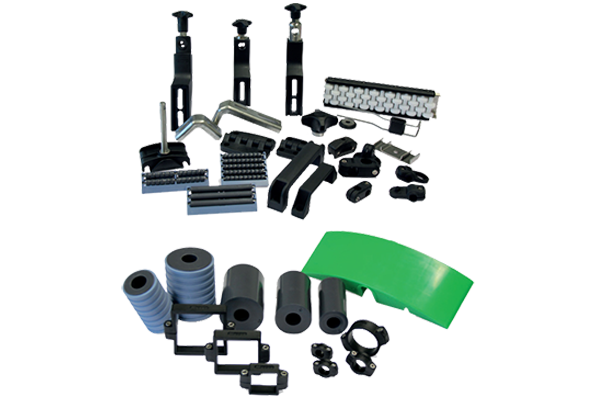

CONVEYOR COMPONENTS

We manufacturing conveyor components to meet customer needs in the mining and construction applications. we complete offering includes rollers, frames, pulleys and belt cleaners, safety and control devices, and dust control systems, with an emphasis on performance and reliability, easily available . Through innovation in design and manufacturing techniques, we provide products that support modern mining practices, both as original components or as replacements in existing systems.

Industrial Conveyors

The basic categories of industrial conveyors are horizontal, inclined, vertical loop and closed-circuit installation. They have a tough chain conveyor which is specifically designed to bear heavy load and vigorous applications. They also bear a Curved section that allows lifting of heavy loads with ease. All components are jig welded -therefore, interchangeability is possible. Our conveyors are all strictly carbon steel construction that has an abrasion resistant divider plate and access panels that give strength and longevity to the conveyors. All our Conveyors come dust-free. We can customize the capacity according to the size of the operation or any other specifications made by our clients. The capacity also depends on the number of workers working there and their efficiency. The electric power usage depends on the capacity of the plant.

Carrying Rollers

We are manufacturer and supplier of Carrying Rollers. We offer these at reasonable rates and are available very easily in market. These are designed using latest technology and high grade raw material.

Specifications:

- 1 + Frame with 3 carrying supporting to belt

- Move the built material

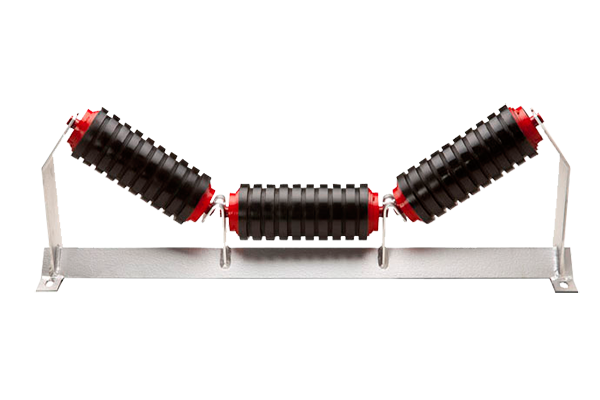

IMPACT ROLLERS

We are engaged in manufacturing and supplying our clients with a comprehensive range of Impact Rollers that are also known as Rubber Rollers. Ideal to be used with Conveyor Idler with Frame, our products are designed and manufactured using high grade raw material like rubber along with advanced machinery on a temperature of 600– 650 C approximately. The rubber belt of this roller rubs down slowly and the rubber used in this helps in enhancing its durability. In addition to this, we test all our products on various parameters to ensure that these meet with international quality standards.

Features:

- Sturdy construction

- Corrosion & abrasion resistance

- Easy installation

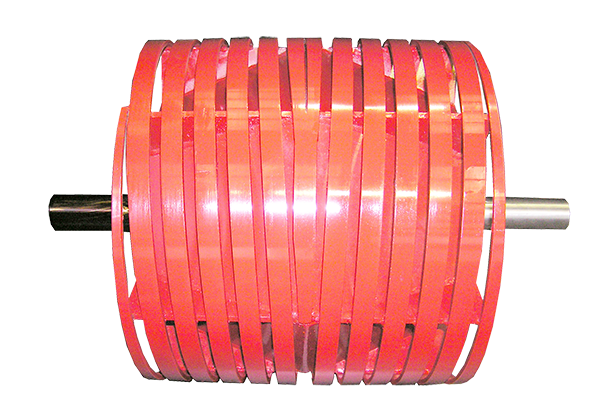

RETURN ROLLER WITH SPACED RUBBER RINGS

Available with us is a comprehensive range of Conveyor Return Roller that are manufactured with as well as without rubber rings. These return rollers are manufactured using high grade raw material and can be customized on parameters like shape and size, as per the clients’ requirements. We ensure the superior functionality and performance of this product line by conducting various stringent tests.

Features:

- Rigid construction

- Resistant to abrasion

- Resistant to corrosion

- Less power consumption

HDPE ROLLER

HDPE Roller is high-density polyethylene conveyor roller

UHMW-PE ROLLER

UHMW-PE Roller is an outstanding plastic roller with the best self lubrication, impact absorbing properties and the highest resistance to abrasion, impact, chemicals of any thermoplastics polymer.

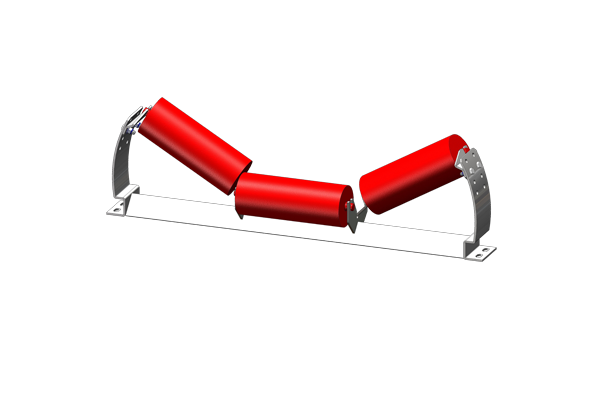

TROUGHING CARRYING IDLER

Troughing idlers are use for conveying bulk materials, and are designed and manufactured with Troughing angels of 20°, 35°, 45°, and any other angle are also manufactured as per customer’s design and drawings.

TROUGHING IMPACT IDLER

Troughing Impact Idler be used under loading points where material impact (lump size,density, height) could damage the belt

SELF TRAINING CARRYING IDLER

We Offering Self Aligning Idlers. These Self Aligning Idlers A+ Grade are made and used for ally type conveyor system. These are used in various industries. These are offered at reasonable rates and are esaily available in market.

Features:

- Dust proof

- Durability

- Highly durable

LAT RETURN IDLER

We are exporter and supplier of Flat Return Idlers. These are offered at affordable rates. These are used in various types of industries and are easily available.

Features:

- Sturdiness

- Long working life

- Durable

V- RETURN IDLER

Where return idler sets comprise two rolls, a support frame is required which supports the idler pair and attaches the idlers to the conveyor frame. This 2-roll design forms the return belt into a ‘v’ trough and these return idler sets are referred to a ‘V’ return idlers. The trough angle of the ‘V’ return idler is usually 10 degrees and this feature has been developed to assist with belt training along the return strand.

GARLAND IDLER

Garland idler set comprises either 3-roll or 5-roll idlers joined together at the ends of their respective shafts by special lugs, to form a continuous ‘chain’ of idlers

Pu Conveyor Roller

We are manufacturer Of Polyurethane / PU Conveyor rollers for Industrial Conveyor Application.Also, we provide PU Coating on metal pipes / rolls.Pu Rollers Sizes Available From Dia 25 MM to Dia 100 MM& Length From 30 MM to 1200 MM

Std Sizes :- PU OD 58 X 400/500/1000 MML, PU OD 60 X 300/400/500/600/700/800/900/1000 MML, PU OD 70 X 400/500/600/800/1000 MML

Applications

- Conveyor System

- Material Handeling Equipments

- Machine manufacturing

- Car Parking System

- Printing Machine

BELT CONVEYOR IDLER

PASHUPATI RUBTECH founded in 2005, leading manufacturer and exporter of conveyor rollers, Conveyor Idlers, conveyor belt, conveyor pulley and other related conveyor components in India. Our products and services has been widely adopted by worldwide mines, coal mine, power plant, steel plant, and so on.

Features:

- Intricately manufactured

- Durability

- Easy to install

Our Main Products:

- Conveyor Rollers: Carry Roller, impact roller, return roller, rubber disc roller.

- Conveyor Idlers: Troughing carrying idler, troughing impact idler, self-training idler, flat return idler, V-return idler, garland idler, 2 Roll assembly idler.

- Conveyor Pulley: Drive pulley, tail pulley, bend pulley, take-up bend pulley.

- Other Conveyor Components: Belt cleaner, impact bed and bar, other related conveyor components.

Other Information

- Minimum Order Quantity: 1 Piece(s)

SELF ALIGNING CARRYING IDLER

Caring Idlers ensures achievement of operational success of belt conveyor in a way. The shell is made from M.S. ERW black steel tube, pressed steel housing made from CRCA sheet, shaft of bright steel bar, sealing system consisting of (back seal, double labyrinth, molded dust cover, a rain cap), single piece fabricated steel idler frame and rollers fitted with size resistant ball bearings that conforms to IS:8598

Range comprises of Troughing (3/5 rolls) for carrying, Return (1 roll) for return side, Troughing Impact Idlers (rubber lined), Flat Impact, & Return Self Aligning.

Minimum Information Reqd. While Sending Enquiry / Order :

- Belt width

- Degree of picking Idlers

- Angle size

- Idler pipe size (OD)

- Overall O.D. in case rubber lined idlers is reqd. for impact idlers.

- Housing material i.e. CRCA steel or C.I. & so on.

- Bearing size, type & make i.e. 6205 or 420205 & so on.

- Quantity in Nos.

- Your detailed drawing, if possible.

V- CARRYING IDLER

Conveyor Idlers are used to carry or convey conveyor belt loaded with bulk material. These carrying idlers are fabricated from different materials such as heavy guage steel tubing or seamless steel tubing, depending upon the requirement and their applications. These idlers are specially designed to provide smooth transition of bulk material for long period of time and are available with impact rings made of special shock absorbing compound. Troughing idlers are use for conveying bulk materials, and are designed and manufactured with Troughing angels of 20° and 30° normally. Idlers of 45° trough angle or any other angle are also manufactured as per customer’s design and drawings.

We can also design manufacture and supply 5 rollers type idlers. Mounting brackets are manufactured out of standard steel sections to have rigidity and stability of the frame. Shafts are manufactured out of Carbon steel bright steel bars suitable for any torsional load and bending movement.

SELF ALIGNING RETURN IDLER

Caring Idlers ensures achievement of operational success of belt conveyor in a way. The shell is made from M.S. ERW black steel tube, pressed steel housing made from CRCA sheet, shaft of bright steel bar, sealing system consisting of (back seal, double labyrinth, molded dust cover, a rain cap), single piece fabricated steel idler frame and rollers fitted with size resistant ball bearings that conforms to IS:8598

Range comprises of Troughing (3/5 rolls) for carrying, Return (1 roll) for return side, Troughing Impact Idlers (rubber lined), Flat Impact, & Return Self Aligning.

Minimum Information Reqd. While Sending Enquiry / Order :

1. Belt width

2. Degree of picking Idlers.

3. Angle size

4. Idler pipe size (OD)

5. Overall O.D. in case rubber lined idlers is reqd. for impact idlers.

6. Housing material i.e. CRCA steel or C.I. & so on.

7. Bearing size, type & make i.e. 6205 or 420205 & so on.

8. Quantity in Nos.

9. Your detailed drawing, if possible.

CONVEYOR DRUM PULLEY

We are providing Conveyor Pulleys that are appreciated by the clients for continuous operation, increased bearing life and less power consumption. In order to offer quality Conveyor Pulleys, we use heavy tubes fabricated from steel plates to manufacture the shell. Further, the pulley shafts are made up of carbon steel machined with proper bore and key way. We are also capable of offering taper lock bushings along with our range of Conveyor Pulleys. The pulley drum is grooved with rubber lagging properly to resist slippage and the shafts are equipped with anti-friction self-aligning ball bearings

RUBBER LAGGED PULLEY

PASHUPATI RUBTECH PVT LTD Pulley Lagging can be done in place, on site, at your local distributor or at the pulley manufacturer. Pulley lagging increases the traction between the belt and the pulley, which in turn reduces load and wear on the drive, belt, pulleys, bearings and take-up. For efficient and economical conveyor operation, proper pulley lagging is integral detail – one that delivers the following key benefits:

- Extends the life of key conveyor components.

- Reduces wear from abrasive materials.

- Prevents belt slippageby increasing the coefficient of friction between the conveyor belt and the pulley.

- Creates a self-cleaning action on the pulley surfaceand prevents the buildup of transported bulk material, water, snow or ice.

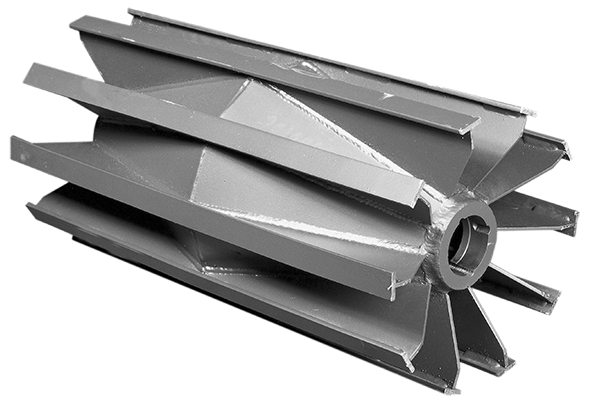

Wing Pulleys

Martin now manufactures heavy duty pulleys offering maximum protection against premature failure in harsh applications. This specialty product line is available as stock, and made-to-order with exceptional delivery time.

- Standard Duty Wing Pulleys

- Mine Duty Wing Pulleys

- Quarry Duty Wing Pulleys

- Quarry Duty “AR” Wing Pulleys

- Special Construction Pulleys

GARLAND CARRYING IDLER

| Belt Width | Face Length | A | B | Mass Idle Set |

| 600 | 220 | 885 | 150 | 15,0 |

| 750 | 270 | 1040 | 180 | 17,1 |

| 900 | 330 | 1195 | 215 | 19,8 |

| 1050 | 390 | 1345 | 250 | 22,5 |

| 1200 | 450 | 1500 | 285 | 25,5 |

| 1350 | 500 | 1650 | 310 | 28,0 |

HEAD PULLEY

We are dynamically engaged in offering the broad range of Head Pulley in the market. These pulleys are commonly used in crane and crushers at the end so that the pulley can make the conveyor belts to move. The material and technology on which this pulley works make it more efficient, durable and cost-effective.

Attributes :

- The shell is made from heavy tubes or fabricated from steel plates

- Pulley shafts of carbon steel machined with proper bore and keyway (taper lock bushings are also offered being optional)

- Shafts fitted with anti-friction self-aligning ball bearings

- Conveyor Belt Drive Pulley up to 2400 mm BW

TAIL PULLEY

Tail/Drive Pulley is located at the discharge terminus of the conveyor. It provides the driving force for the conveyor. In order to increase pulley life and traction, it often has a larger diameter than other pulleys.

Pashupati can supply pulleys with hot vulcanized rubber lagging, plain or grooved, as required by client. Different patterns of grooving such as herringbone or diamond can be provided to increase tractive friction under dirty or wet conditions. Diamond grooves have the advantage of being installed in any orientation, regardless of belt direction.

Heavy Duty Conveyor Belt

Our clients can avail from us an optimum quality range of heavy duty conveyor belt, that are specifically designed to withstand high wear and extensively used for conveying various hot and oily materials including coke, hot fertilizers, asphalt, grit, ore, coal, rocks, stones, clinkers and riprap etc. To conveyor logs and other forest products, this belt has a bare back (slider bed) that ensures easy operations.

Our heavy duty belts are precision engineered and undergo strict testing on the parameters of tensile strength, elongation at break, maximum abrasion loss etc. These heavy duty conveyor belts find application in airports, shipyards, thermal plants, construction, mining, processing and various other industries. We have specialization in offering these heavy duty belts in both standard and customized specifications.

Features :

- Heat resistant

- Oil resistant

- Special wear resistant covers

- Ideal for carrying sharp & rugged materials

DRUM PULLEY

- Drum Conveyor Pulleys are constructed with a standard crown face unless otherwise specified

- Not designed for use with steel cable or high modulus belts.

ROLLER CONVEYOR

The Roller are very important component of belt conveyor. They are present along the entire Length of the conveyor, support the belt and moving the materials loaded on the belt. The diameter of the idler could be correctly selected according to the belt width and Travel speed. We produce f60mm, Ǿ 63.5mm, Ǿ 76mm, Ǿ 89mm, Ǿ 102mm, Ǿ 114mm, Ǿ 127mm, Ǿ 139mm, Ǿ159mm. They almost cover all belt width requirement General steel Roller consists of idler shell, spindle, bearing, bearing house, seals Equipment and axial fixed unites.

Features:

1) Steady running, reliable quality and reduce maintenance;

2) Less movement longitudinally, rotating smoothly, extends the life span;

3) Various bearing housing and sealing structure are available for the customer’s choice;

4) Multipass labyrinthine sealing, preventing the mixed dirt and water immersed;

5) Manufacturing by steel pipe especially for of high precision roller, ensuring the strong load, low shaking and less noise.

FLEXIBLE CONVEYOR

We offer our clients Flexible Roller Conveyor, which are used for material handling applications in different industries such as automotive, food and packaging etc. Made from premium grade components, these conveyors are renowned for robust construction and effective conveying of bulk material. Further, we also custom design these conveyors as per the specifications provided by our clients.